Marine container terminals are the driving force behind the global supply chain, meaning that the operations of a single terminal can have a far-reaching impact. Developing a yard decking strategy is thus a necessity for optimizing terminal performance. Sound strategy empowers you to handle containers efficiently with cutting-edge tools like graphical planning software.

Let’s discuss what a yard decking strategy is and what to consider when developing one.

What is a Yard Decking Strategy?

A yard decking strategy is a way to organize a terminal yard, making critical decisions about where each type of container should go (and why). It informs terminal operating systems, impacting traffic, productivity, and customer satisfaction. The best strategies make container handling seamless.

Your yard decking strategy will direct import, export, and yard-to-yard container movement.

Effective yard decking strategy is all about efficient organization. Because of the key role it plays in vessel operations, it’s one of the most critical aspects of vessel planning.

Why Terminals Need a Yard Decking Strategy to Organize Containers

Organization is a necessity in the yard because, without it, containers will get mixed up, increasing the need for additional handling and slowing down operations. A container should, ideally, only be handled twice: once when being moved to or from the vessel and then again when being moved to or from the truck. Anything beyond that likely indicates an inefficiency.

Sorting containers by port, size, status, and other factors provides order, and an effective yard decking strategy defines how this segregation should be done.

The Benefits of Having an Optimized Decking Strategy for Your Operations

Developing a yard decking strategy is a necessary part of container terminal planning and design that takes time and effort, but it will benefit future operations in many ways.

A terminal yard with an optimized decking strategy experiences:

- Increased productivity and efficiency

- Optimal use of yard space

- Better traffic flow and less terminal congestion

- Reduced gate turn times

- Quicker vessel turnaround times

- A safer working environment

All of these optimizations work to reduce redundant moves and more accurately estimate labor needs, leading to more efficient and profitable operations.

Factors to Consider When Creating a Yard Decking Strategy

What does the optimal yard decking strategy look like? The best strategy for a terminal yard will depend on several factors. Consider the following while developing your strategy:

1. Category: Import vs. Export

Import and export yards have different kinds of traffic and activities, so categorizing containers as imports and exports is one of the most significant separations you can make.

After a vessel is unloaded, containers are moved to the import yard, where a truck will pick them up. This traffic activity is constant in most terminals but can vary depending on factors including the time of year, etc.

At the same time, loading and other export activities need to run smoothly.

Terminal-operated utility tractor rigs or UTRs need to move containers from the yard to the quay, where terminal workers load the vessels. Keeping these operations separate is critical for keeping things moving, maintaining gate and vessel productivity, meeting service level agreements (SLAs) and deadlines, and satisfying customers. For an efficient flow and minimal container handling, keep import containers close to the gate and export containers close to the vessel.

2. Geography and Logistics: Vessel Service and Port Rotation

A handful of connected factors critical to a yard decking strategy are vessel service (destination), the order of stops (port rotation), and the availability and length of both vessels and berths.

It’s inefficient to have more than one vessel on the same service at a port at the same time, so you can expect there to be only one vessel at a time for a specific service. Port rotation should ensure that the containers you unload first are on the most accessible part of the vessel. Stacks of containers can extend from well below deck up to a few containers above deck, depending on the capacity of the vessel.

When there is a longer vessel of significant TEU capacity, the length of the berth needs to accommodate that of the vessel. Since longer berths have more cranes, sending the longest ships to the longest berths will ensure they can be worked faster.

Allocating based on both service and length will help prevent disruptive traffic that inhibits other terminal activities. It can be challenging to organize, but berth planning tools can analyze vessel schedules to help determine an optimized plan.

3. Vessel Stability

Container weight has a direct impact on vessel stability, so it’s a critical consideration in a decking strategy. A vessel that is loaded with uneven weight distribution can lead to:

- Vessel control issues

- Poor sightline

- Listing

- Improper landing of containers

- Containers falling off the ship

- Vessel capsizing

Remaining within the structural weight limits of a vessel is also important for vessel stability and preventing damage. One method for managing weight is using the four-corner average. Stress and weight peak at the point where the corners of four containers meet, making it an ideal spot for measuring stress.

Another best practice is to position the heaviest containers at the bottom of a stack. When planning movements, deck heavier containers together to facilitate allocating spaces for them that can accommodate their weight.

4. Traffic Patterns and Container Location

Managing traffic is a big part of keeping terminal operations efficient, so traffic patterns between the gate and the yard and between the yard and the berths should be as controlled as possible. Many gate transactions are unidirectional, but mixed transactions are more efficient.

Traffic-related factors to keep in mind include but are not limited to:

- Allocation placement: Position export allocations such that trucks can reach them before import allocations; they should ideally drop off before continuing to a pickup.

- Traffic routes: Establish clear routes to ensure trucks can access areas quickly, safely, and without confusion.

- Traffic rules: Make sure driving rules in the terminal are obvious, and use signage to indicate one-way routes, places where entry is banned, and anything else that needs to be communicated to drivers.

- Access priority: If there are high-traffic areas of the terminal where truck access needs to be maximized, reallocate space to accommodate as needed.

5. Operation Type: Grounded vs. Wheeled

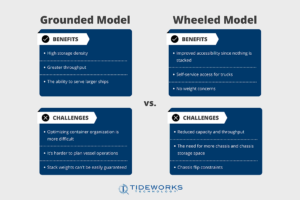

Terminals typically contain both grounded (stacked) and wheeled (chassis) operations. The differences between these operations will inform your yard decking strategy. Their relative pros and cons break down as follows:

Benefits of the Grounded Model:

- High storage density

- Greater throughput

- The ability to serve larger ships

Challenges of the Grounded Model:

- Optimizing container organization is more difficult

- It’s harder to plan vessel operations

- Stack weights can’t be easily guaranteed

Benefits of the Wheeled Model:

- Improved accessibility since nothing is stacked

- Self-service access for trucks

- No weight concerns

Challenges of the Wheeled Model:

- Reduced capacity and throughput

- The need for more chassis and chassis storage space

- Chassis flip constraints

In most cases, wheeled terminals will start stacking containers when they run out of space or chassis but reserve as much space for wheeled operations as needed to maximize throughput.

6. Priority Service Agreements

Company-specific service agreements will also directly affect your terminal layout. Containers of VIP and priority customers will need to be more accessible so they can be moved quickly. Putting these containers on a chassis and parking them near the gate is one strategy to ensure they can be moved in and out without delay.

Use Spinnaker to Carry Out Your Yard Decking Strategy

The key to creating an effective yard decking strategy is understanding which of the factors discussed above you should prioritize. At the end of the day, you understand your terminal’s operations better than anyone else and can create a configuration that improves upon existing processes.

Once you’ve planned your yard decking strategy, Spinnaker can help you implement it. This graphical planning tool utilizes information such as weight range and port rotation to segregate your containers and make allocations according to your strategy, making sure your plan is carried out exactly as designed. It’ll also facilitate assessment, adjustment, and management of future yard planning.

Spinnaker’s graphical planning will improve your productivity, accuracy, and operational efficiency. Contact Tideworks to learn how Spinnaker will enhance your yard decking strategy.