4 Data-Driven Solutions for Intermodal Terminal Challenges

Today’s intermodal terminals are facing a crisis of efficiency. Increasing demand, supply chain disruptions, shrinking margins, and more intense competition are driving terminal operators to seek novel solutions to the age-old question “how do we do more with less?”

In the last decade or so, smaller terminals have been feeling the pinch as larger terminal operators have found new ways to deliver services to previously niche areas. While smaller operations may not generate immense freight revenue, they are still critical to the intermodal network.

But even larger terminals are having to contend with receding margins as greater customer demands limit terminal operators’ abilities to pass on increasing operational costs. In general, the industry realizes that it needs new solutions to confront these growing problems.

This article will discuss how data access and visibility help solve the industry’s efficiency problem, as well as four specific problem areas that increased efficiency can address.

What Does Efficiency Look Like in Intermodal Terminals?

Terminals have a limited footprint, and it’s generally difficult to add more land, which means that if they want to increase throughput, they need to find ways to use their space and resources more efficiently.

Intermodal terminals achieve efficiency gains when they better utilize their yard and reduce turn times. When terminals can precisely orchestrate truck pickups and drop-offs, the drivers can move in and out of the terminal more rapidly, improving traffic patterns and overall efficiency.

Efficiency isn’t an abstraction. It involves daily concrete steps to better allocate limited resources and get work done faster.

Struggling with complex data challenges that don’t align your business and leave you wondering where you can really improve your operations?

How Terminals Set New Efficiency Goals

To set new goals, terminals define specific metrics, rate how the operation is performing, and then decide on reasonable and necessary improvements. Terminals then use operational data to track their progress towards their goals.

On a daily basis, terminals look at lifts per man-hour — the industry standard for measuring the amount of work getting done. The more lifts completed in a day, or another time period, the more efficient the operation.

Beyond that, terminals look to improve the speed with which they can move trains and trucks in and out of the facility. The longer this takes, the more it costs the terminal, so even incremental gains can make a big difference.

4 Data-Driven Solutions to Intermodal Terminals’ Common Challenges

Efficiency gains can be found by solving four challenges most intermodal terminals contend with. The solution? Data and intelligent automation.

Improving Gate Processing Times

Most terminals aim to have trucks in and out gated at specific intervals. However, it’s extremely difficult to improve this metric when a terminal lacks a reliable method for accurately measuring gate times. Without data, the process becomes guesswork and can often lead to traffic congestion, long turn times, and frustrated drivers.

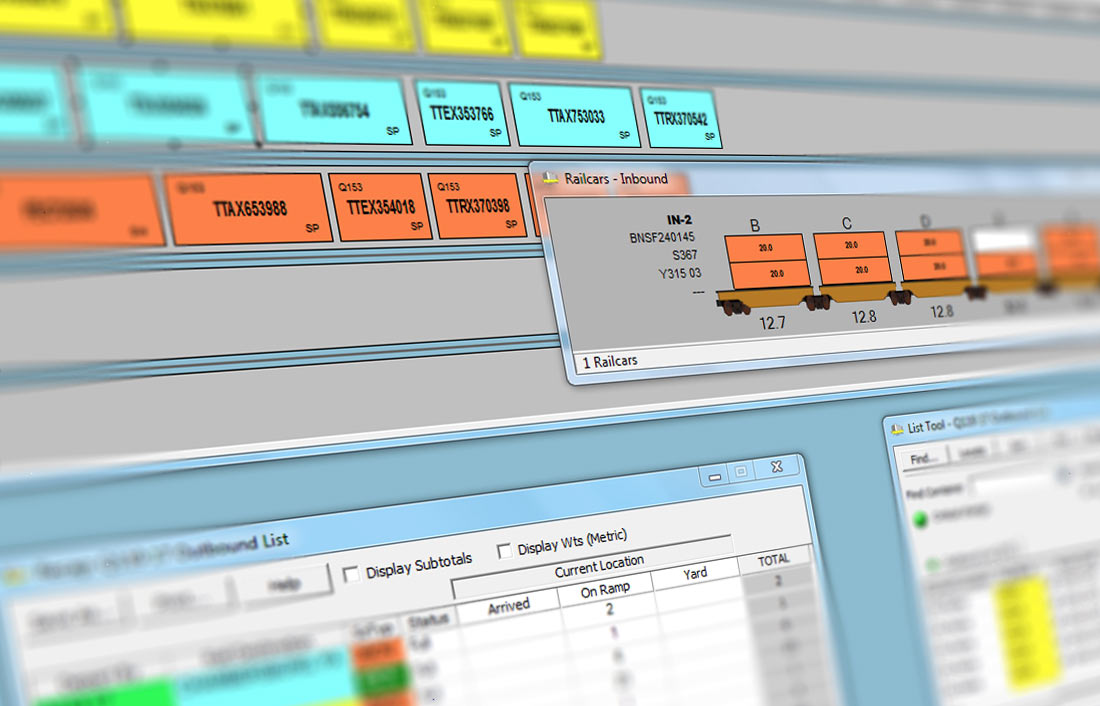

In order to capture granular data and get a real-time look at gate processing times, intermodal terminals need a comprehensive software solution like a terminal operating system. Our Intermodal PRO TOS allows terminals to collect this critical data and define accurate KPIs to measure progress. Intermodal PRO also maximizes planning efficiency allowing terminal operators to gain control over every aspect of their operation including moves to and from the gate.

Optimizing Over-the-Road Truckers

In the past, it was believed that terminals could be better at transporting a carrier’s cargo without trucks.

New software tools are changing this mentality. With Tideworks, terminal operators can design locations for specific cargo and then tell truckers precisely where to unload or pickup. This is much more efficient than having OTR truckers exchanging cargo in a central location because it eliminates unproductive moves.

By optimizing trucker routes, the terminal offloads the work to the carrier.

Maximizing Yard Space Utilization

Maximizing Yard Space Utilization

Yard utilization is a critical part of any long-term efficiency plan. When a terminal yard is poorly organized, operators must move cargo more than it should, leading to longer turn times.

Tideworks’ flexible TOS solution, IPRO, gives terminal operators tools to quickly define regions of their yard for specific purposes. They can then direct truckers to those regions and even change them day to day.

Cargo that’s normally deposited at the south end of the yard might occasionally need to be transferred to the north end for different track access. The yard allocation can be changed on the fly, and the next container that in-gates will immediately receive new instructions.

Minimizing Planning Time

Container and cargo planning play a critical role in the operational efficiency of a terminal. The process of manual or even digitized planning can be manual and slow. Tideworks offers a number of features that reduce or remove planning time from the equation.

Live Lift automates cargo from the gate to trackside stacks, letting the TOS do the planning after an operator establishes business rules. It can also escalate gate moves and reduce truck dwell time.

As a complement to Live Lift, Auto-Plan lets terminal operators choose a grouping of containers in the yard and have the TOS plan every container to its proper rail car in seconds. The system plans the cargo out using the rules an operator configures for their terminal and allows planners to focus on other terminal planning activities rather than manually planning all outbound containers.

IPRO and Tideworks Data Platform: Measure and Analyze Efficiency in Real-Time

Tideworks Data Platform is Tideworks’ data platform that connects with our IPRO TOS. It gives terminal operators extremely granular access to data collected from all facets of the terminal’s operations. The data can be sliced and examined in real-time, as situations change throughout the terminal.

Examine specific areas, down to the equipment level. Look at individual lifts or groups of lifts over any period of time you require. Tie in maintenance and financial data to get a complete picture of your operation from moment to moment.

Our Tideworks Intermodal TOS solution will give you the tools you need to find efficiencies you never could have found on your own. It provides a holistic view of your terminal data and revolutionizes the way intermodal terminals of every size carry out their day-to-day operations.