While the shipping industry has changed as technology has evolved, the fundamentals have remained the same since the beginning. The faster cargo is loaded on and off a vessel, put in its proper place in the yard, or placed on a truck or train, the easier it will be to turn the vessel to its next planned destination.

However, intelligent and intuitive technology offers terminal operators more opportunities to maximize productivity and increase operational efficiency. These technologies and tools take the ongoing challenges of manual planning management and apply intelligent design and machine learning to help terminals solve complex issues that would have been nearly impossible to tackle otherwise.

Learning the history of planning in container terminals can help you understand where this industry has been. Then, we can turn our attention to the challenges that can be mitigated through innovation.

How Terminals Historically Executed Planning Management

Even as recently as a few years ago, planning at a terminal was done using a simple pen and paper. All containers were listed and planned using chits, or simple text printed on sticker paper. All of the import containers arriving aboard a vessel were listed on these simple square stickers, then moved around on a grid drawn on either a piece of paper or a whiteboard. Each grid would have space representing each vessel’s position in the bays, then the stickers would be moved to a different grid representing the space in the yard.

Once the chits were placed in the yard grid, this grid would be finalized, and copies would be made for all relevant staff. These copies also provided laborers, crane operators, and yard managers with their instructions on which containers each would be unloading and where they would eventually be placed.

The Challenges of Manual Planning

There are a few universal challenges of manual planning.

The first is that it’s a manual, slow process. After years of making these diagrams and grids by hand, terminal operators will learn the most efficient way to load and unload a vessel. However, this learning experience is complex and entirely dependent on repetition. Additionally, even if the terminal operator is adept at creating physical plans, it takes time to place the chits and double-check the grid.

The old way of planning is also prone to costly human errors. Every now and then, a chit would fall off the board and get lost or stuck to the bottom of someone’s shoe. Because of this simple error, now a container shipment is lost or needs to be rerouted or replaced, all of which come with costly fees. Every time a load or unload is missed, the line charges these fees to the terminal operator.

What is a Graphical Planning Tool?

Instead of doing a vessel load and unload by hand, now there are graphical planning tools that can take these physical processes and objects and make them virtual.

These graphical planning tools help terminal operators visualize how space is being used (both in their yard and on each ship) and allows them to better plan for loads and unloads between locations.

Instead of seeing each load as a small one-dimensional sticker, it lets you see the objects in their space and plan for each move to a new area.

We’ve found that the more the user interface mirrors the physical processes or looks like the physical reality surrounding that process, the easier it is to understand and use. In general, many terminal operators find it easier to use planning tools that are graphical rather than text-based. These features allow them to:

- See each container on a ship and in the yard

- View an entire ship at once

- Zero in on a bay or a single stack of containers

- Select containers and move them to specific spots in the yard

- Create a plan that takes each container from the vessel to the yard, then to each truck which will take them out the gate

Key Capabilities and Benefits of a Graphical Planning Tool

Provides a More Precise Way for Planners to Get a Complete Picture of Their Terminal and Plan Accordingly

Understanding your inventory and container loads is simplest when you can visualize how the space is used. This helps terminal operators answer questions like:

- Where is there extra capacity?

- Which areas are full?

- How are containers mixed?

The graphic visual interface and color-coding capabilities provide a complete picture for planners, giving them an accurate container and equipment inventory and the ability to visualize how their space is being used.

Simplifies the Process of Planning Moves

If all your equipment is accounted for accurately within these tools, planning moves and giving orders can be executed entirely electronically. It’s as simple as clicking and dragging an icon to a new location.

Helps Avoid Costly Errors and Fees

No planner wants to leave a container behind. In this situation, the terminal becomes responsible for expediting that shipment and is culpable for having missed it in the first place.

With overnight trucking or air freight charges becoming more exorbitant by the day, these fees add up quickly. The damage is substantial when you account for the impact on the shippers, the business owners, and the customers in terms of both finances and inconvenience.

Having everything visually accounted for in the planning system helps terminal operators avoid many of these challenges and risks and makes the entire system far less prone to error.

How Smart Graphical Planning Can Maximize a Terminal’s Operational Efficiency

There are a variety of ways that graphical planning tools and technologies can maximize the operational efficiency of operators organizing planning in container terminals.

Making these improvements isn’t just about reducing errors. Making these moves more streamlined and efficient helps offer terminal operators more time to focus on other aspects of their job that require their attention.

Here are some of the most important ways these smart graphical planning tools can impact operational efficiency terminal-wide.

Reduces Time Needed to Plan Critical Moves

In general, when you plan electronically, the processes and workflow are much faster. By reducing the time needed to plan these crucial operations, these tools allow terminal operators to focus on other aspects of their overall workload.

Eliminates stowage errors: Leaving behind or losing containers are costly errors that were not uncommon when complex moves were planned using stickers and a whiteboard. By simplifying these moves electronically where no container can be left behind, it helps to eliminate these costly and inconvenient stowage errors.

Effectively optimizes yard space: This is especially critical right now as many terminals face overcapacity. Containers need to get loaded onto vessels properly, efficiently, and in the correct order. Graphical planning helps organize your yard based on vessel rotation, container type, container size, and many other important data points. If a yard has a variety of containers all mixed together, it will require extra handling and unproductive moves that eat up both time and money.

Reduces turn times to increase cargo volume: Graphical planning tools help to reduce extra handling, which reduces turn times. By helping terminals plan how containers get loaded and unloaded into the yard and onto vessels, trucks, or rail more efficiently (by container size, type, port, etc.), graphical planning reduces the number of unproductive moves or set-asides that must be done to keep the yard organized. These faster and more productive turn times can increase the cargo volume passing through the terminal.

6 Ways Spinnaker Can Help a Terminal Optimize its Operational Efficiency

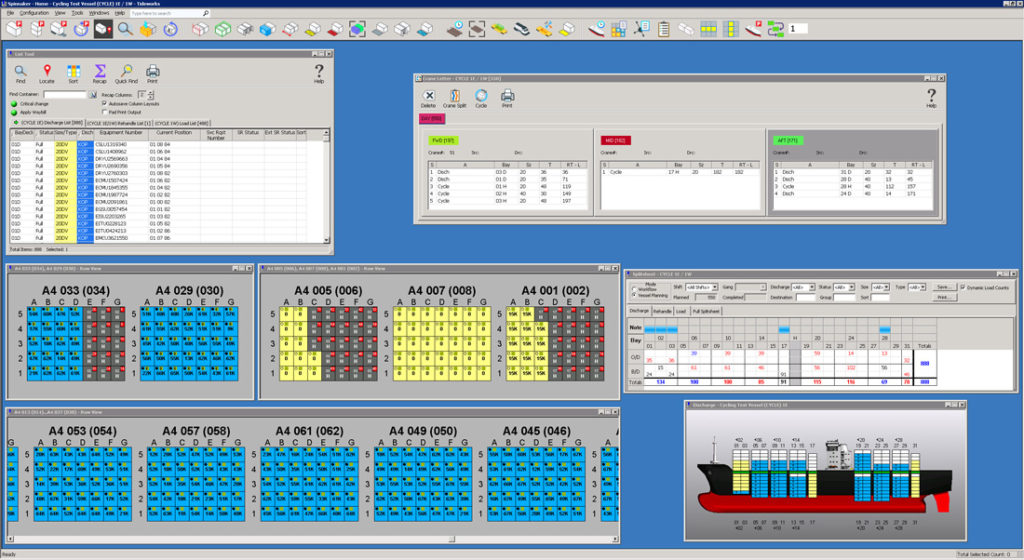

Spinnaker is Tideworks’ graphical vessel, berth, yard, and rail planning into one workspace. Here are some of the ways our software can help your terminal.

1. It’s Easy to Integrate into Existing Operations

The last thing any terminal operator wants is to start from scratch with a brand-new workflow when implementing new software.

Thankfully, Spinnaker can be implemented in a way that does not interrupt your current workflow. Instead, it complements how you already work, offering shortcuts and creative solutions to ongoing issues that will help you get complex work done faster.

2. Spinnaker Offers User-Driven Reporting and Customized Lists

You know best what types of lists are useful for your terminal. Spinnaker’s find and list tools make it easy for users to create customized lists (or reports).

This has been our focus from day one – giving users the tools they need to invoke any data, organize it, and share it how they like. We think of the find and list tools as the nerve center of Spinnaker. Using these tools, it’s easy to isolate and filter any type of container in your yard, using hundreds of search parameters configured into a customized order of your choosing.

Whenever you run a search, you can name and save it privately or publicly, then duplicate or export it. Once the results populate, it’s easy to sort, drag and drop, and build out any report you need.

3. Supports Automatic Stacking Cranes

Autonomous or automatic stacking cranes (ASCs) that work without an operator receiving instructions through the equipment’s programmable logic controller (PLC). Then, this data is translated into movements by the crane.

The crane will know whether each container is swappable with another driver based on their pickup requirements and can automatically uncover, pickup, and deliver that container to the trucker in the transfer lane along the block the ASC serves.

Offering these automated cranes more information helps them be aware of what’s happening around them and allows them to be more accurate in their movements.

4. Eliminates Operational Bottlenecks with Yard Pools and Allocations

Spinnaker helps enable processes to make your yard decking strategy more automated and convenient.

These features and options also allow users a high degree of control over where they place containers in the yard, allowing them to fill space better while identifying key patterns. This helps eliminate operational bottlenecks and balance traffic between different spaces within the yard.

5. Smart Automatic Set-Asides

If you need to make a terminal convenience move, the last thing you want is for it to be time-consuming or inefficient. If you repeatedly find yourself moving the same container, it’s a sign that your placement strategy needs work.

To help minimize these unproductive moves, Spinnaker uses an algorithm to determine the best location where a set-aside can remain until it’s needed.

6. Utilizes Color Coding and Symbols for Container Identification

When making moves within a yard, there are so many different options. It’s like looking at a game of Tetris, but instead of unique pieces, they’re all perfect squares.

Spinnaker’s color-coding and symbol lexicon allows terminal operators and managers to clearly identify containers by a variety of attributes, including:

- Origin port

- Destination port

- Status (empty or full)

- Line operator

- Size type

This makes container status and destination easy to see, allowing operators to better plan larger moves without having to stop and identify individual containers.

Maximize Terminal Efficiency with Spinnaker Planning Management System

The smart graphical layout and list planning capabilities of Spinnaker are just some of the features prized by terminal managers and operators all over the world. Want to learn more about how well it can integrate with your current workflows? Contact us today to learn what Spinnaker can do for your terminal.