As a terminal manager, you undoubtedly face the problem of bottlenecks in your terminal yard.

Congestion buildup has many causes and the resulting disruption can happen before you know it. To clear it up, you need actionable, real-time information about delays, container moves, handling equipment, trucker queues, communication issues—anything and everything that results in terminal yard operational clutter.

Prepare for Problems

Container yards at ports are often vast, and congestion is a common occurrence. You may be experiencing some, if not all, of the following problems at your terminals we speak:

- Delays in vessel arrival resulting in trucks waiting for cargo discharge.

- Terminal equipment assets being reallocated to accommodate higher priority operations.

- An influx of too many trucks in the yard at one time causing a traffic jam.

- The wrong container is transferred from a stack to an over-the-road or terminal truck.

- Container handling equipment (CHE) malfunction or breakdown.

- Truck drivers getting out of order in the queue to pick up containers.

- Shift change occurring at suboptimal efficiency.

- Miscommunication between equipment operators and truck drivers.

Capturing Data

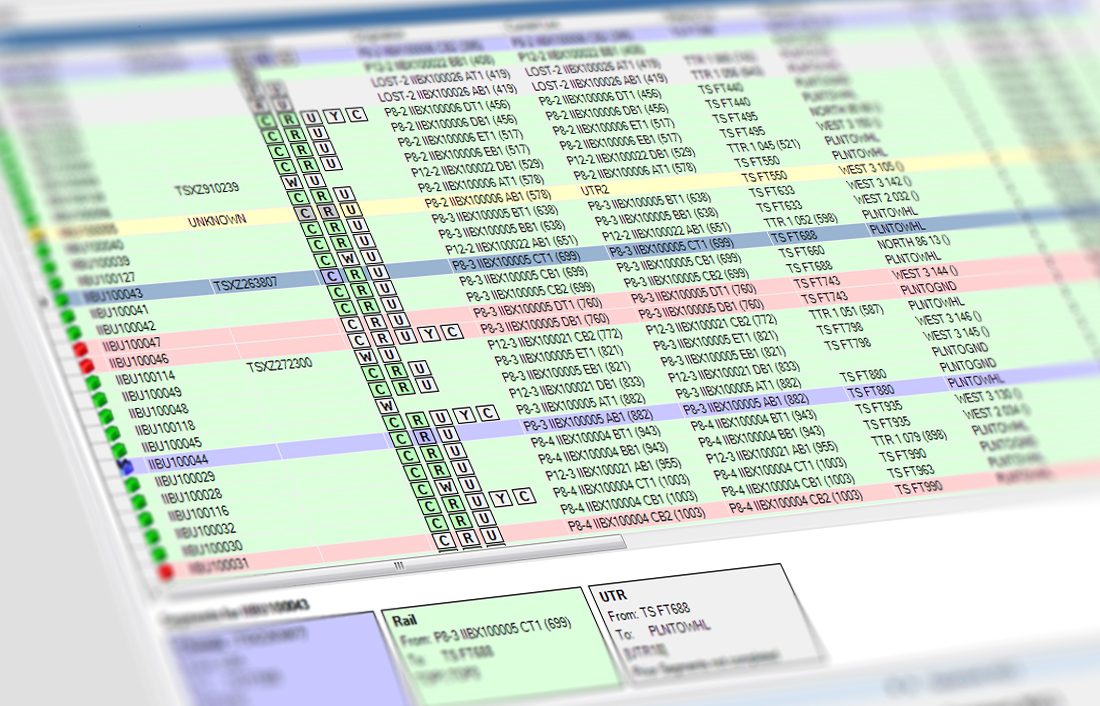

Quay and yard crane productivity are vital to the continued good health of terminal operations. An operations manager demands immediate, real-time information and clear communications with crane operators. They’ll ask questions like, “what is the current status on priority moves?” Given that information, what is the best and most expedient way to deliver move instructions to the operators? You can replace your current paper instructions and radio communication practices with an automated dispatch system, which will optimize crane and CHE operations. You can capture the data you need to reduce congestion and improve productivity in your terminal.

Updates in Real-Time

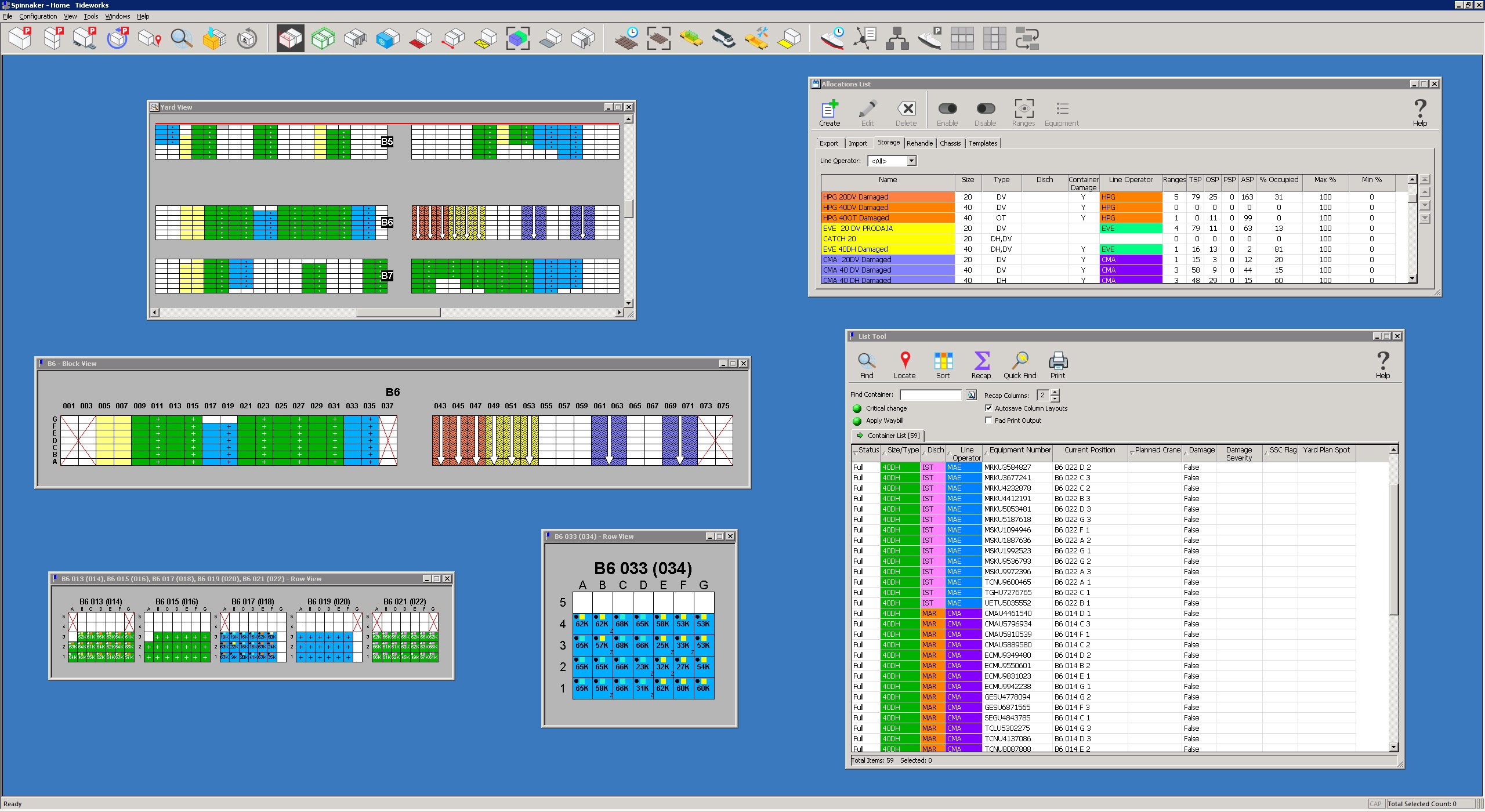

As an operations manager, think of intuitive, scalable technology as your new friend. For instance, with an automated dispatch system, as soon as an equipment operator completes a move the TOS receives a real-time update of the new container status. Touch screen functionality for CHE operators provides instantaneous communications for greater efficiency and accuracy. The automated dispatch system you need offers a highly configurable setup that you can modify to your specific requirements. You can also take advantage of an adaptable priority system so that high-priority container moves, such as those to a vessel or train, take precedence.

Planning Management

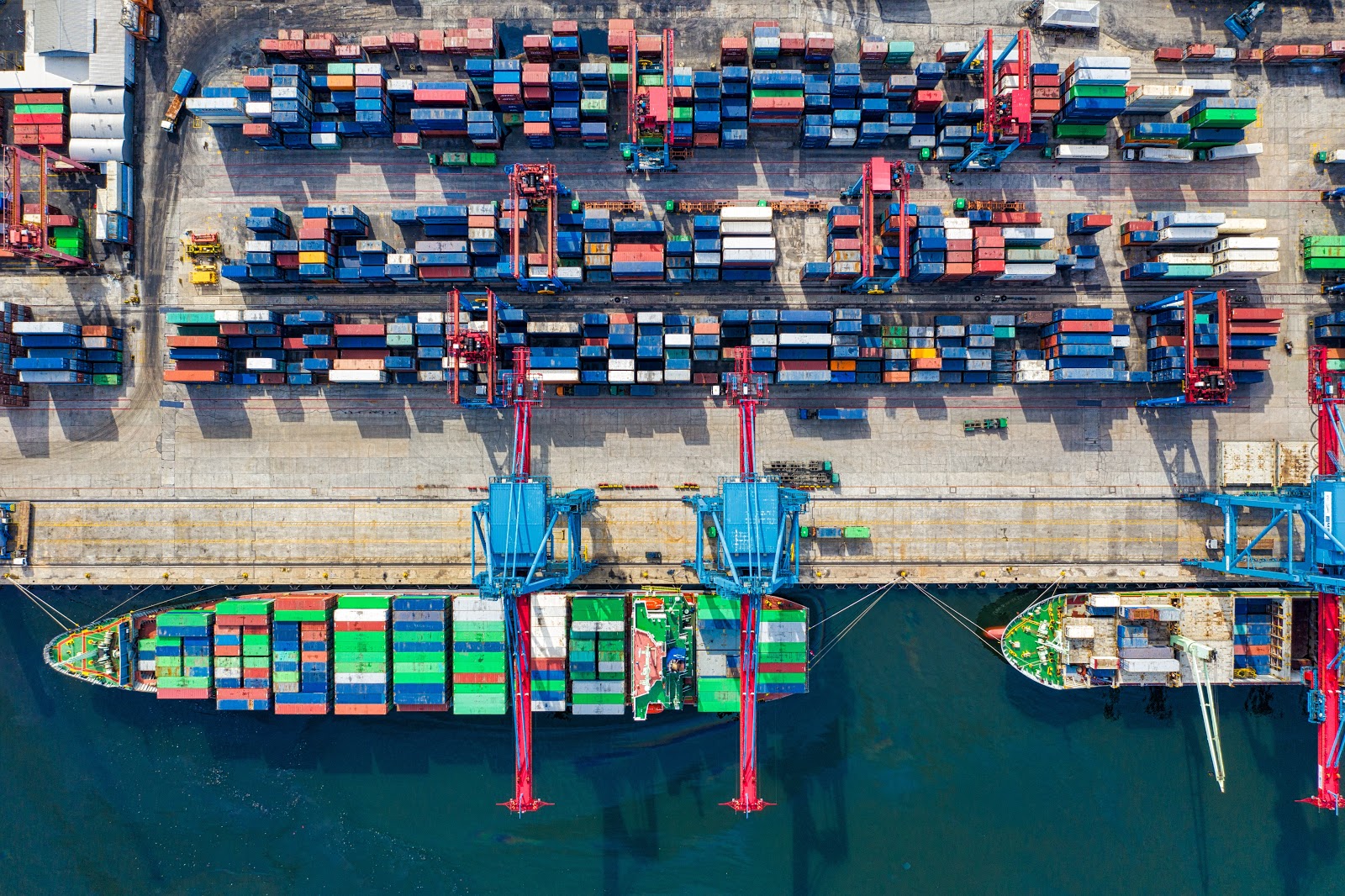

Ports that handle container shipments require vast amounts of terminal yard space to accommodate the ever-growing container stacks, as a result of the ever-increasing vessel size. Attention to the efficiency of yard operations is therefore essential. Ultra-large container ships may discharge upwards of 4,000 containers in a single port call and require the service of 6 or more cranes. There is a need for state-of-the-art technology that can optimize container location and inventory information. The same program can allow the user to create electronic dispatch work orders by shift, then distribute the information automatically to the appropriate personnel. What you need is smart graphical planning elements with optimized execution instructions, in one system, so that you can reduce inefficiencies and problem areas and return your terminal to peak operation.

Questions and Answers

To manage container yard disruptions, perhaps you and your staff are still depending on manual operations to get the information you need for decision-making. You’re becoming increasingly frustrated by the time it takes to make phone calls, radio personnel, obtain bits of information from third-party sources, and plug in the daily changes and additions to Excel spreadsheets. Every marine terminal has unique requirements for effective operations management.